Nice one! You're interested in finding out more about our great products! Have a read and then afterwards why not wander over to the shop at the wall you're in and grab some GEKCO!

What’s in your chalk bag? The environmental cost of climbing chalk

There’s something oddly comforting about the ritual of chalking up. Dipping into that familiar powder, clapping your hands, watching the white cloud drift away before launching into a climb. Chalk is one of climbing’s small constants. But how often do we stop to think about where it comes from… or what it costs?

The unassuming white dust filling your chalk bag may have travelled a long way and left a far heavier environmental footprint than expected. The majority of climbing chalk is mined in China, often with little transparency or sustainability. But, the good news is that alternatives exist, and you can make the decision to choose chalk that doesn’t cost the planet.

Chalk - the basics

After his enrollment in a gymnastics class in 1954, the godfather of bouldering John Gill had no idea his practices would lead to a major revelation in climbing. Once discovering the benefits of chalking up before the rope climb, he realised you may as well chalk up for a climb too. Within a decade, climbers were smearing chalk on their hands worldwide, and the rest is history…

Climbing chalk is primarily made from magnesium carbonate (MgCO3), a mineral which absorbs moisture therefore keeping our hands dry. Perfect, right? Well not exactly. The problems arise with how this magnesium carbonate is sourced, where it’s sourced from and the environmental impacts that are tied to this.

Where does it come from?

Over 70% of the world’s magnesium carbonate is mined in China. Most of that production is concentrated in a small region of Liaoning - an industrial province in northeast China. Only a small handful of mining and processing factories here produce the magnesite, yet the impact is devastating. From above, the region appears to be a ski resort. But the miles upon miles of white smears across the landscape aren’t snow - it’s magnesite dust.

As a result of the mining process, cities and towns in Liaoning such as Haicheng - a small suburban area, are covered with this dust. But a ‘dusting’ of chalk isn’t the problem. Once the chalk dust has been exposed to water, it cakes-up and forms a hard shell all over the land, infrastructures and crops. This hydromagnesite crust causes a huge environmental impact.

THE ENVIRONMENTAL IMPACTS

As opposed to the strict regulations that Western countries employ for environmental protection, China has often faced criticism for its comparatively lenient approach to environmental protection. In the West, the mining industry is required to follow rigorous standards, such as treating/preventing wastewater runoff, restoring mining sites to their natural state after use, and avoiding industrial development in ecologically sensitive areas that host protected species or unique plant life. These policies aim to balance economic growth with ecological sustainability. In contrast, China's rapid mining expansion has frequently outpaced environmental conservation, leading to widespread pollution and habitat degradation. Although recent years have seen some policy improvements and clean-up campaigns, enforcement remains inconsistent, raising concerns about the long-term impact on the environment, including air and water quality, natural habitats, and overall ecological balance.

An ecologist at the Chinese Academy of Sciences in Liaoning, De-Hui Zeng, has spent many years documenting the impacts caused by these factories. His research has directly implicated magnesite mining in soil degradation, large-scale plant death, and reduced microbial activity. In a 2009 study he stated “A mass of dusts, mainly magnesium carbonate and magnesium oxide, is produced when exploiting and producing magnesite, which contaminates soil and damages plant via basifying and hardening soil, and disturbs the balance between soil soluble magnesium and calcium”.

In 2015, De-Hui Zeng released one of the first studies which explored the reasons behind why magnesite mining actually affects the soil in surrounding land. Up until this point, scientists and ecologists knew that magnesium dust was affecting the soil and therefore the crops, but they could never understand why. Zeng himself said “The deposition of magnesium (Mg)-rich dust from magnesite mining activities has resulted in serious land degradation. However, the main factors limiting plant growth in Mg-contaminated soils are unclear”.

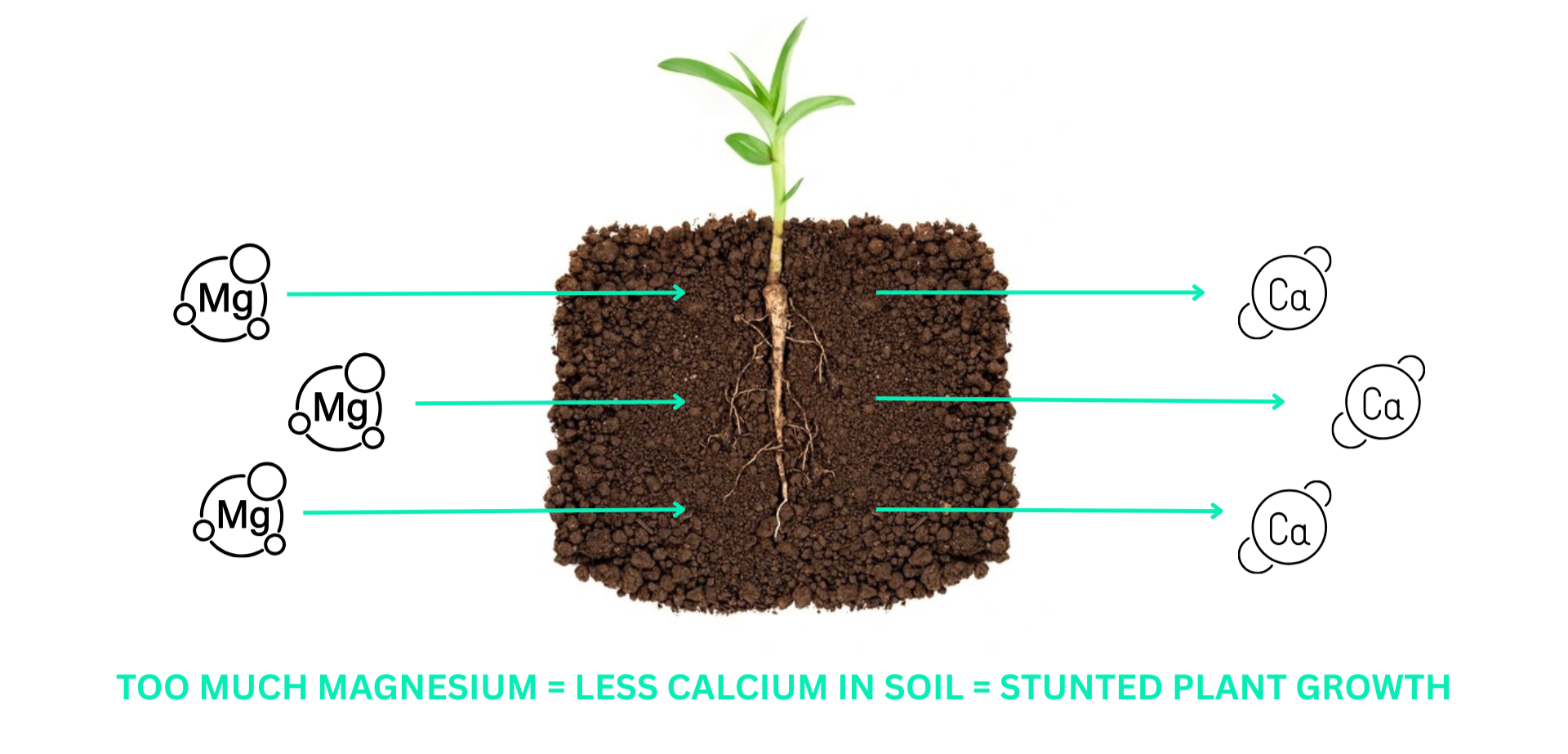

In this 2015 study, Zeng uncovered that the main reason crops struggle to grow under these magnesite-coated conditions is because there isn’t enough calcium in the soil. In simplistic terms, soil can only hold a limited number of positively charged nutrients, so when there’s too much magnesium present, the calcium is ‘blocked’ and can’t be absorbed by plants. Plants rely heavily on calcium during the growth stages, so this lack of calcium prevents crops from growing, therefore reducing all agricultural prospects in these regions of Liaoning.

BEYOND THE ENVIRONMENT

Magnesite clouds aren’t only affecting the land though. As well as ethical issues around labour in China, the residents of these towns and cities are directly affected by the magnesite mining that is happening in their backyards. Magnesite dust and waste production gases fill the air, posing serious health concerns for the families that spend their days engulfed by it. Although they have been protesting against the mines for years, little effort is being made to solve the issues affecting their lives every day - because profit comes before planet and people for so many industries.

HOW DOES THIS AFFECT US?

A lot of individuals like to take the ‘removed stance’ when approaching environmental issues such as these - “Well it doesn’t directly affect me therefore it isn’t my problem”. However it does affect you, and every climber that uses mined chalk. The reality is that mined chalk is impure. It is a well known (and proven) fact that the mining process results in contaminants being present. The chalk you use, which claims to be 100% magnesium carbonate, almost certainly isn’t. Containing performance reducing impurities like calcium carbonate and traces of heavy metals such as lead, arsenic, asbestos and mercury, mined chalks specifically from this region of the world are not always what they seem. Just think about how every single time you chalk up, you’re potentially exposing yourself to these, and then decide if it's worth using mined chalk or not…

THE SOLUTION

When we first started GEKCO, we knew about these negative environmental impacts of mined chalk, and we weren’t happy to settle like other brands. We went searching for an alternative - and discovered seawater-processed chalk. As a byproduct of the desalinisation process (removing minerals from seawater), magnesium carbonate sourced from this process utilises solar evaporation and is significantly more environmentally friendly than mined chalk. With none of the contaminants produced from mining, seawater processed chalk is the purest form of magnesium carbonate out there, and as it’s sourced from Europe it has a much lower carbon footprint.

Our mission is to change the climbing industry and make chalk greener. As manufacturers, we have the responsibility to source the best and most sustainable raw materials that is possible in the current climate - which is exactly what we do here at GEKCO. As mentioned in this article in Climbing Magazine, maybe in the future outdoor companies will be held to the same standards as clothing brands, publishing the origin of their products. But ultimately, it’s up to you as consumers to be conscious of your choices when buying a product. With hundreds of options for chalk out there, and only a couple which are sourced sustainably, as a community we need to be making the decision to buy chalk that doesn’t cost the planet.